Toll Free: Red Deer 1-866-342-0032 Grande Prairie 1-877-402-3066

Isolation Equipment Services - All Rights Reserved

Features |

Details |

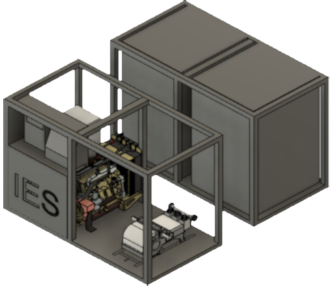

Compact and Easily Accessible |

Skid units are compact and moved with ease on PAD locations. All controls are user friendly and operated at ground level. |

Fail Safe Over Pressure System |

Equipped with a 15K pressure relief valve to prevent over pressuring, in addition a factory burst disc protects the pump from over pressuring. |

Unique Hydraulic Operating System |

Main hydraulic system is pre-set that controls the amount of flow to the pressure pump, which regulates the maximum desirable discharge pressure |

Hydraulic Controls |

Pumper is equipped with a high/low range which provides easy and gentle induction of fluids when pressure testing and starting ball displacement. Low range provides operator with more control and options |

Secondary Hydraulic Source |

Backup hydraulic system for operating the XL series and or remote valve systems |

Manifold (annulus pressure system) |

Annulus pressure can be maintained during ball launching operations. |

Pressure Fluid Readings and Recordings |

Full Electronic Recorder displays both lines pressure and rate with manual backup readings |

Technical Specifications |

HP |

Flow Rate |

Working Pressure |

Normal Pumper |

243 |

Up to 150 liters/min |

15000psi (103.5 MPa) |

Large Volume Pumper |

375 |

Up to 190 liters/min |

15000psi (103.5 MPa) |

Features |

Details |

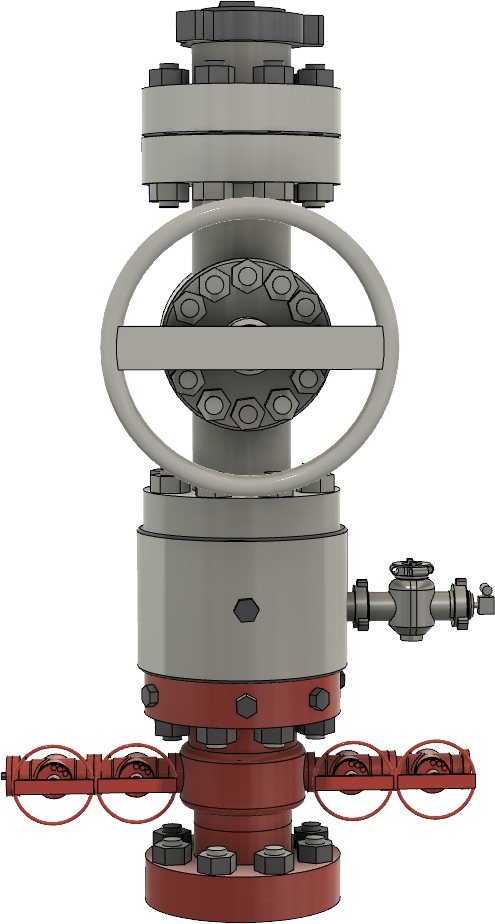

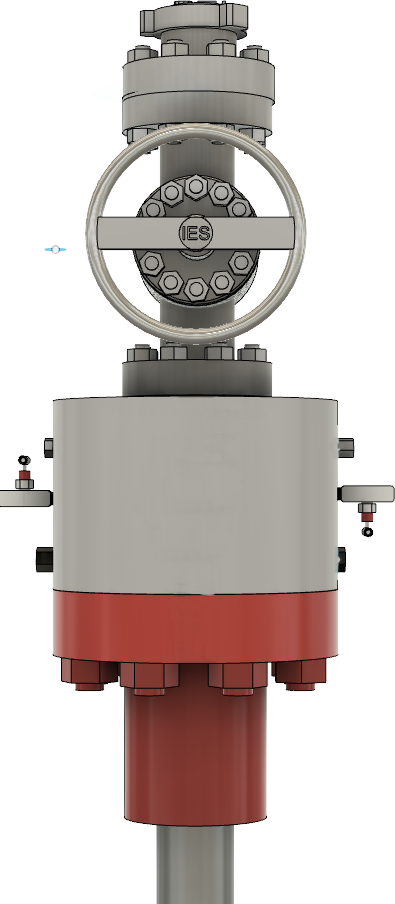

Upgrades Existing Wellhead to 10K(69 MPa) or 15K (103.5 MPa) WP |

A sealed high pressure sub is connected to the dognut |

Multi Seal Connection |

High pressure seals are pressure tested to comfirm their integrity prior to the frac job |

Unique Venting System

|

Vent valve preferred to be connected to the annulus casing valve or vented to the atmosphere |

Annulus Pressure Back Up |

Annulus pressure provides back up support for the high pressure sub |

Dognut Seals Become Dormant

|

Dognut seal leak will not jeopardize the job |

Full Bore For Back Pressure Plug Passage |

Sub exhibits a full bore to accommodate downhole passage |

Universal Tubing Hanger Sizes

|

7 1/16" 2K, 3K, and 5K Connects to 2 3/8", 2 7/8", 3.5" and 4.5 tubulars |

Universal Frachead Connections |

3 1/16" 10K, 15K 4 1/16" 10K, 15K |

Features |

Details |

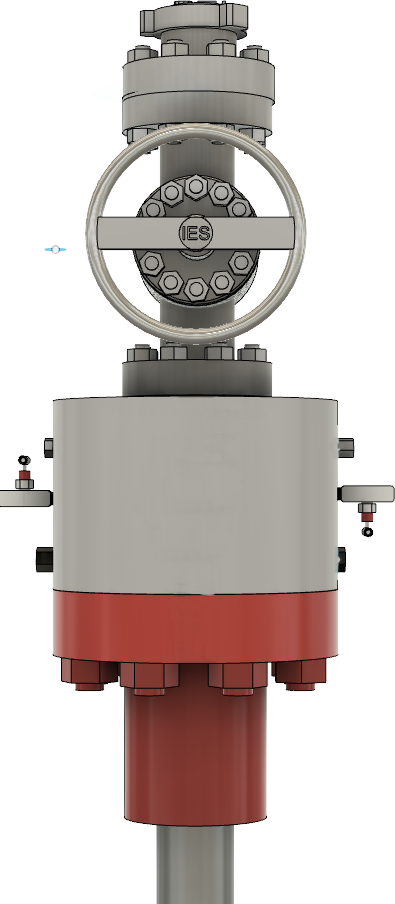

Upgrades Existing Wellhead to 10K (69 MPa) or 15K (103.5 MPa) |

Isolation Bonnet connects to casing bowl and seals 6" of casing stub |

Multi Seal Connection |

High pressure seals are energized + pressure tested to confirm their integrity prior to frac job |

Universal Casing Bowl Connections |

11" - 2K,3K,5K / 9" 2K,3K,5K |

Universal Casing Sizes |

4 1/2" (114.3mm) - 5 1/2" (139.7mm) |

Universal Frachead Connections |

3 1/16" 10K, 15K 4 1/16" 10K, 15K 5 1/8" 10K 15K |

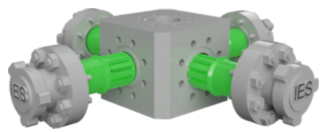

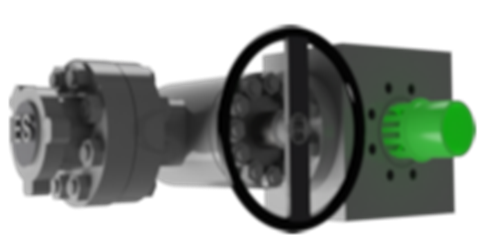

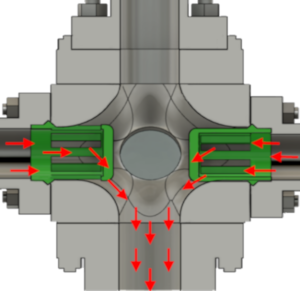

The slotted screen technology has proven to work extremely well in both the Buffalo Head (or Multi Port unit) and the Coil Headers. The results have been outstanding (refer to the IES Case Study report); we have quite the collection of debris, which includes multi sized rocks, pump parts and even a certification band that did not go down hole. This has our clients smiling and confident that unintentional pieces are not working their way down hole, which could seriously compromise downhole equipment and even create premature screen-outs. The results are much fewer screen-outs, downhole tools work more efficiently and reduces coil costs; all which positively reflect in your costs to complete the Wells. Our screens SAVE stages.

In addition the design allows for the fluids to disperse through a slotted area that in total triples the area (12.56 increasing to 36 sq inches) which results in managing erosion to perfection.

5" Bore Flow max rate of 8m3/min per inlet

Slotted Debris Screen

Pressure Rating |

10K (69 MPa) and 15K (103.5 MPa) Wp |

Pumping Rates |

4" Bore flow max rate of 3m3/min per inlet 5" Bore flow max rate of 8m3/min per inlet |

Opposing Fluids |

IES recommends opposing fluid entry at all times |

Sour Gas |

Manufactured to NACE Sour Gas Specifications |